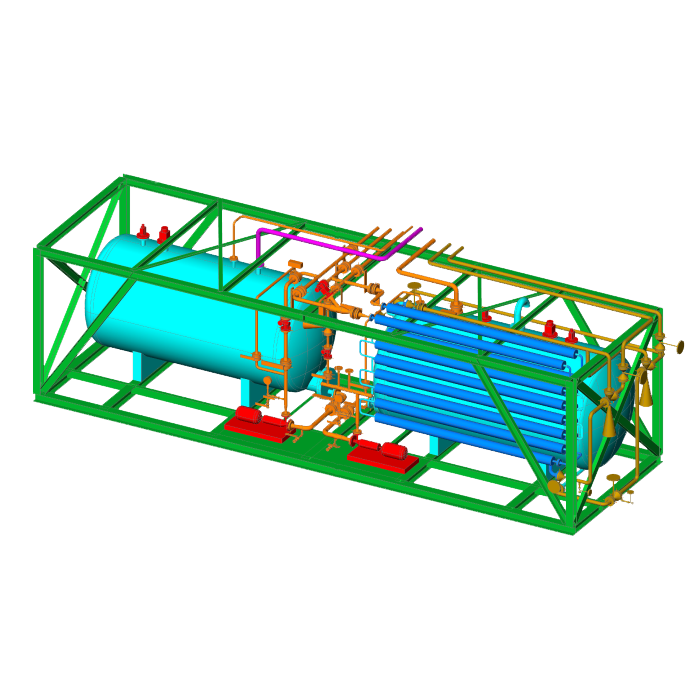

Plants for paints, inks, water-based paints

DIMONT IMPIANTI designs complete plants, plant sections or revamping for the production of water-based paints, solvent paints, enamels, fillers and polyurethane resins. Thanks to the professionalism and experience of its technicians, DIMONT IMPIANTI has the know-how for developing and sizing from revamping to the complete plant: from raw material storage silos and tanks to the dosing and mixing section, finished product storage tanks and packaging lines.

Teamwork for major projects

On large projects, Dimont Impianti works in teams with engineering partners able to bring specific skills, from the development of engineering alone to the entire supply of the complete "turnkey" plant, as well as the design of entire production sites, including utilities, packaging lines with particular attention to an efficient study of the layout of all logistics areas from production to storage.

Production of paint plants: how we work

The, typically batch, paint plants are managed at every stage, from the storage and management of raw materials to the dosing of thousands of different formulations, mixing and packaging by fully automated management systems, such as PLC with SCADA systems or, in the most complex management systems, using DCS that provide connectivity that can be fully integrated with higher-level systems such as MES and ERP.

The data are tracked completely throughout the process flow in a logic of traceability and integration of “Industry 4.0”.

Particular care is taken in the design of the paint production plant to treat flammable gas effluents, through the sizing of various alternative abatement systems such as combustors or post-combustors, cryogenic systems, activated carbon filters, or solutions that are even more customizable and integrated in the production reality such as conveying flammable effluents to the burners of the heating plant or to the torch.

No less important in this type of plant, for the purposes of safety, is the attention to the perfect sizing of blanketing nitrogen inerting systems by correctly selecting the flow rates and the reducer and breather valves.

In the specific sector, DIMONT IMPIANTI designs complete plants for the production of water-based paints, solvent paints, enamels, fillers and polyurethane resins.

Types of paints produced in Dimont plants

The Dimont Impianti company manufactures plants for the production of different types of paint.

-

ALKYDS

- Oil phenolic alkyds

- Vinyl alkyds

- Nitro

- Chloroalkyds

-

VINYLS

- Two-component polyurethane

- Two-component polyacrylic

- Two-component acrylic

- One-component acrylic

- Two-component epoxy

- Two-component epoxy-acrylic

- Epoxy-vinyl

- Epoxy-phenolic

- Epoxy esters

Solvent paints

Dimont Impianti designs and builds solvent paint plants. In detail, we build plants for the production of:

-

WATER-SOLUBLE PAINTS

- One-component acrylic

- One-component alkyd

- One-component polyurethane

- Two-component epoxy

- Two-component polyurethane

- Two-component acrylic

- Silicone

Water-soluble paints

In addition to solvent paints Dimont Impianti designs plants for water-soluble paints that include: